Understanding the Importance of High-Quality Vapour Barriers

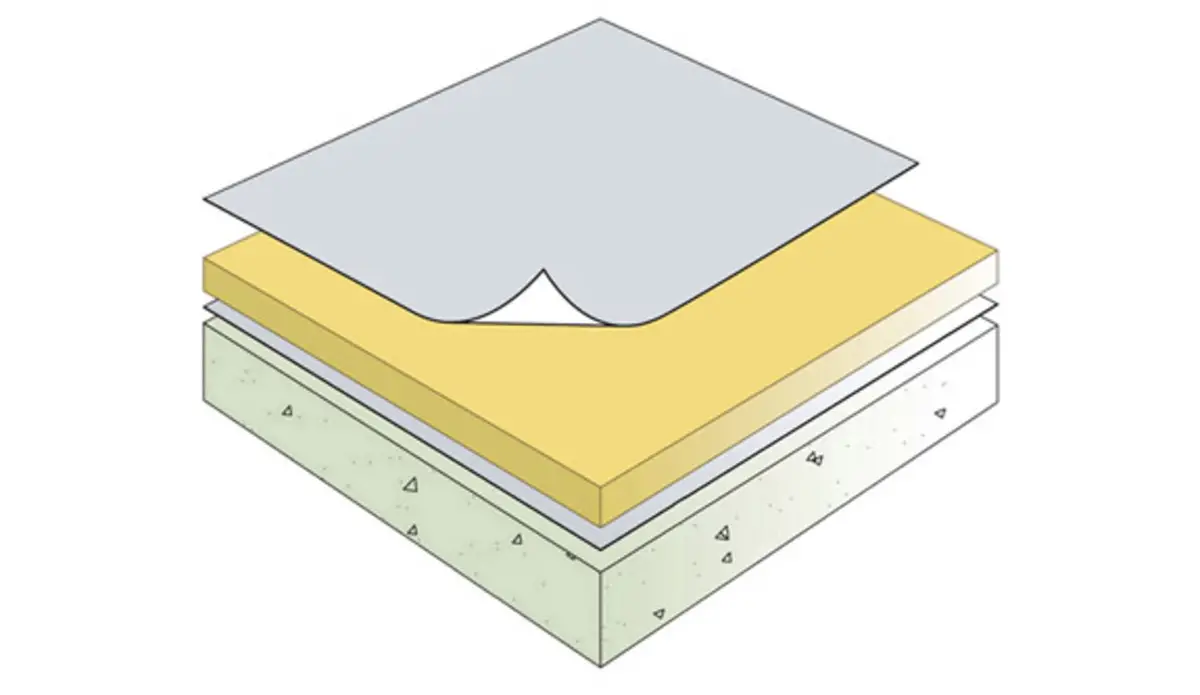

A vapour barrier is a material designed to prevent the movement of moisture-laden air from passing through the building envelope. It helps control condensation and moisture-related issues.

Using a high-quality vapour barrier in a roof build-up can offer several benefits that contribute to the overall performance, longevity and energy efficiency of a building.

Why a High Quality Vapour Barrier Matters

Here are some of the key benefits of using a high-quality vapour barrier in a roof build-up:

Moisture Control

One of the primary functions of a vapour barrier is to prevent moisture from entering or exiting the building envelope. Moisture infiltration can lead to issues like mould growth, rot and deterioration of building materials. A high-quality vapour barrier effectively controls the movement of water vapour thus reducing the risk of moisture-related problems.

Condensation Prevention

In our cool damp climate, warm indoor air can carry moisture that, when it comes into contact with colder surfaces within the roof assembly, can condense into liquid water. This can lead to structural damage and insulation performance degradation. A vapour barrier minimises the chances of condensation by blocking the movement of warm, moisture-laden air into the colder parts of the roof assembly.

Improved Energy Efficiency

Moisture infiltration can compromise the insulation’s thermal performance, causing it to become less effective at maintaining indoor temperatures. By preventing moisture from entering the insulation layer, a vapour barrier helps maintain the insulation’s R-value, resulting in improved energy efficiency and reduced heating and cooling costs.

Enhanced Durability

Moisture can weaken the structural integrity of building materials over time. With a vapour barrier in place, the risk of moisture-related deterioration, such as wood rot or corrosion of metal components, is significantly reduced. This contributes to the long-term durability of the roof assembly.

Air Quality and Health

Moisture infiltration can create a conducive environment for mould growth, which can lead to poor indoor air quality and potential health issues for occupants. A vapour barrier helps prevent the conditions that promote mould growth, maintaining a healthier indoor environment.

Prevention of Thermal Bridging

Some insulation materials can lose their thermal resistance when exposed to moisture. A vapour barrier protects insulation from becoming damp, preventing thermal bridging and ensuring consistent thermal performance across the roof assembly.

Protection of Roof Components

Moisture can damage roofing components like decking, timberwork, and even structural elements, leading to premature failure and increased maintenance costs. A vapour barrier shields these components from moisture-related damage, prolonging their lifespan.

Insurance against construction flaws

Even if the initial design of the roof assembly does not anticipate significant moisture infiltration, environmental factors and construction flaws can still lead to moisture-related issues. A vapour barrier acts as an “insurance policy” providing an additional layer of protection against unforeseen moisture problems.

Conclusion

When selecting a vapour barrier, it’s essential to consider factors such as the climate zone, the roof assembly’s design, the type of insulation used and the local building regulations. Using a high-quality vapour barrier that is compatible with the specific requirements of the roof build-up will help maximise the benefits outlined above and contribute to the overall performance and longevity of the building.

Got a Question? Ask Tecron

For more in-depth roofing insights, trust Tecron. Tecron’s Technical Team can aid in the design and delivery of the optimum roofing solutions for your upcoming roofing project. To get started, contact us at sales@tecron.ie, call us on +353-91-353545 or follow us on LinkedIn.

Choosing Fully Adhered vs. Mechanically Fixed Membrane Roof Systems

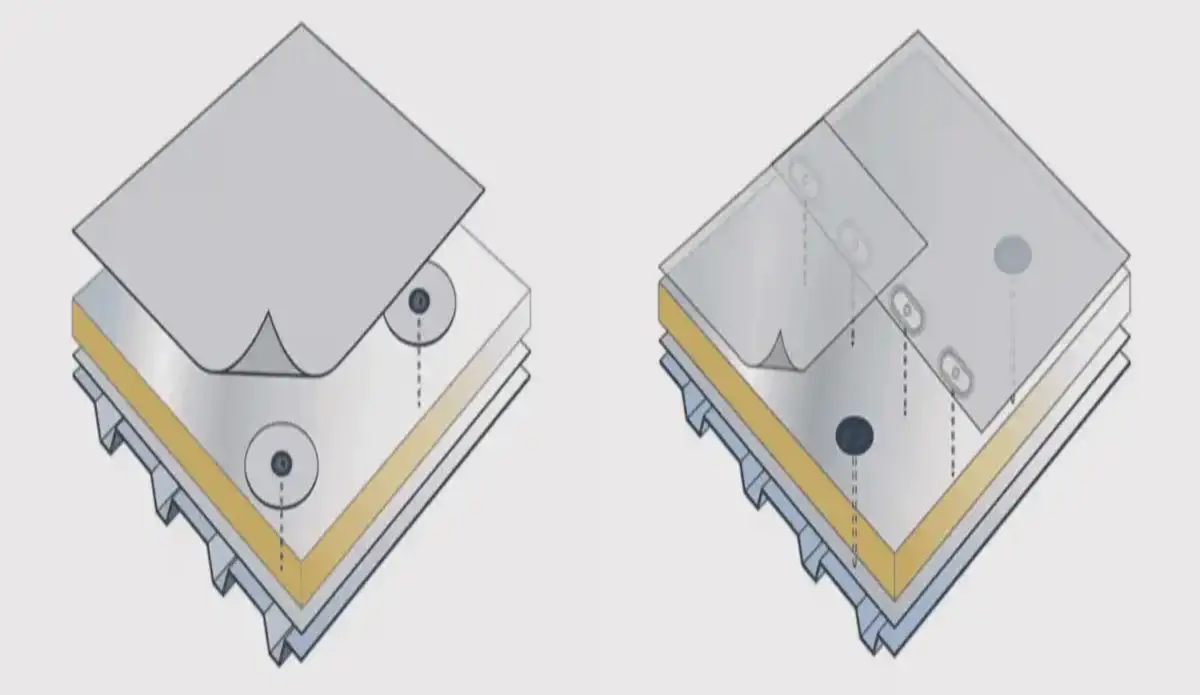

“Fully adhered” (fixed with adhesives) and “mechanically fixed” (fixed with screws) are two different methods of installing roofing materials and each has its own set of advantages and disadvantages.

The choice between the two depends on various factors, including the type of roofing material, climate, budget, and building structure.

We explore the distinct advantages of each roofing method to help you decide what’s the best option:

Advantages of a Fully Adhered Roof

–Wind Resistance: Fully adhered roofs are generally more wind-resistant than mechanically fixed roofs because the roofing material is securely glued or adhered to the substrate, reducing the risk of wind uplift.

–Watertight Seal: The adhesive used in fully adhered roofing systems can create a continuous seal under the membrane, minimising the risk of water travelling through the roof from leaks and any water infiltration.

–Aesthetics: Fully adhered roofs often have a smoother and more aesthetically pleasing appearance because there are no visible fasteners or penetrations on the surface.

–Noise Reduction: The adhesive layer can help dampen sound, making fully adhered roofs quieter during heavy rain or hail while also preventing and flapping of the membranes in windy conditions.

–Enhanced Insulation: Fully adhered roofing systems can provide better insulation properties due to the absence of fasteners that could create thermal bridges.

–Durability: The adhesive bond helps distribute the weight and stress evenly across the roofing material, potentially extending the roof’s lifespan.

–Low Maintenance: Fully adhered roofs typically require less maintenance over time because there are no exposed fasteners or seams that may degrade.

-Reduced Installation Time: The installation process for fully adhered roofs is typically, but not always, quicker than mechanically fixed systems. This is especially true on concrete roof decks where mechanically fixing a roof membrane and insulation involves pre-drilling thousands of holes.

Advantages of a Mechanically Fixed Roof

-Cost-Effective: Mechanically fixed roofing systems are often more cost-effective to install because they require fewer materials and less labour than fully adhered systems.

–Easier Repairs: If a portion of the roof is damaged, it can be easier and more cost-effective to repair or replace individual sections in a mechanically fixed system.

–Flexibility: Mechanically fixed roofs are more adaptable to a variety of substrates and can accommodate changes in building structure or expansion more easily.

-Reduced Installation Time: The installation process for mechanically fixed roofs is typically, but not always, quicker than fully adhered systems, which can help reduce labour costs.

Ventilation: Mechanically fixed roofs can allow for better ventilation under the roof membrane, which can be important in some climates to prevent moisture buildup.

Conclusion

Ultimately, the choice between a fully adhered roof and a mechanically fixed roof depends on the specific needs and priorities of the project.

Factors such as climate, budget, building structure, and roofing material will all play a significant role in the decision-making process.

Take Your Project to New Heights with Tecron

For more in-depth roofing consultants, Tecron’s Technical Team can aid in the design and delivery of the optimum roofing solutions for your upcoming roofing project. Contact us at sales@tecron.ie, by phone on +353-91-353545 or follow us on LinkedIn.